Local News

Researchers at RIT pioneer new self-healing materials that promise to make 3D-printed products stronger and more durable than ever before

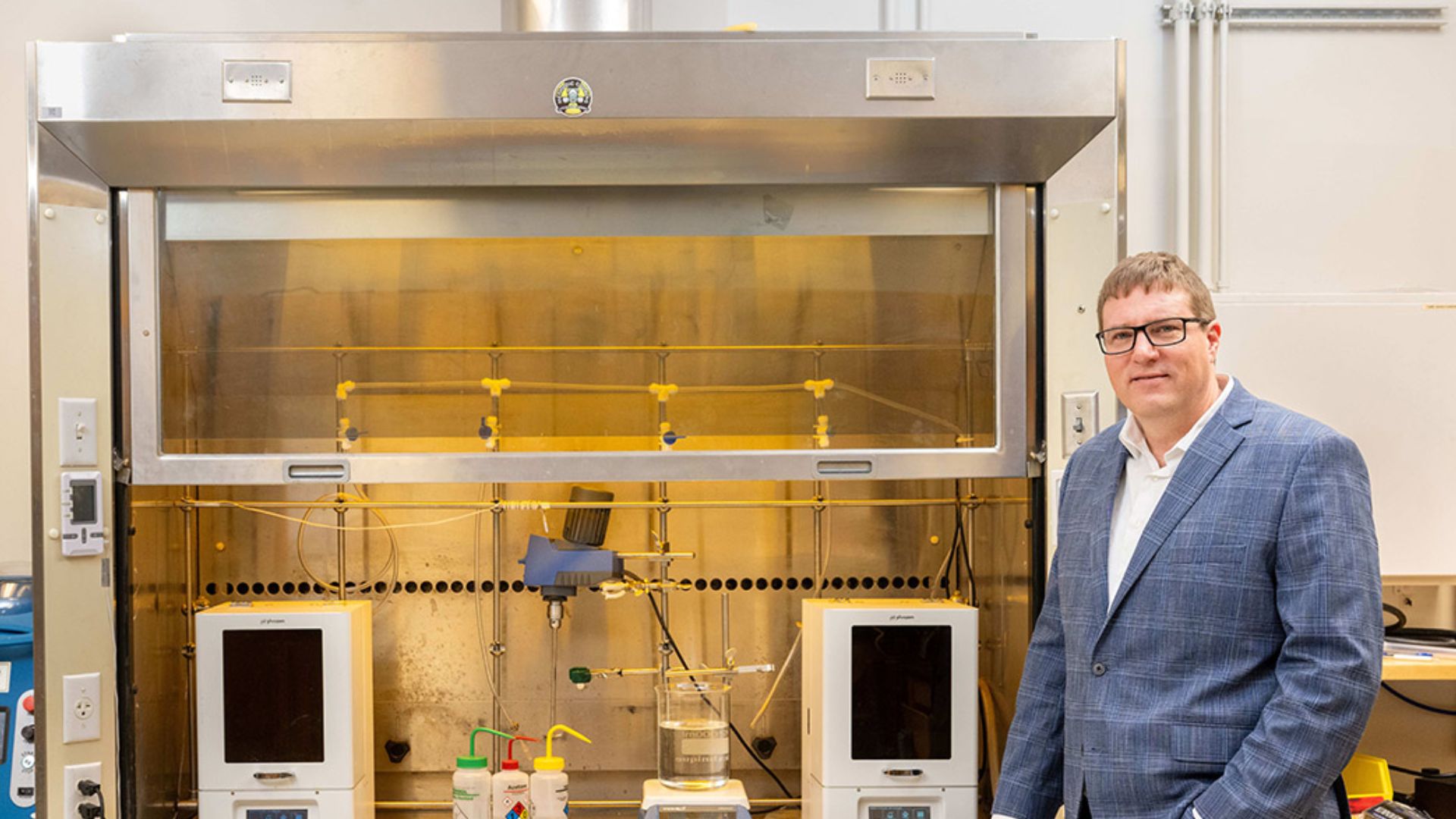

Rochester, New York – In a quiet lab filled with the hum of 3D printers, researchers at the Rochester Institute of Technology (RIT) are shaping what could be the future of manufacturing – materials that can repair themselves. This groundbreaking work, led by Christopher Lewis, represents a leap toward creating longer-lasting, more reliable products through additive manufacturing.

Lewis and his research team have been developing a new class of self-healing materials designed to address one of the most persistent problems in 3D printing — brittleness and cracking over time. Their innovation centers around a stimuli-responsive photopolymer solution, a liquid resin that behaves much like superglue before printing, but once cured, gains the remarkable ability to mend itself after damage.

The material solidifies selectively through a lithography process, layer by layer, forming intricate 3D-printed parts with a built-in capacity for self-repair. This concept, long imagined in material science circles, is now edging closer to real-world applications thanks to this team’s work.

“There is a lot of interest today in materials that can heal, or self-repair, themselves. In 3D printing, the ability to build more reliable parts that have these healing actions can benefit multiple industries and provide cost savings. Companies can rely more confidently on the strength of materials being used for high-precision equipment such as printed electronics, soft robotics, or prosthetics for the aerospace, automotive, and biomedical fields,” said Lewis, an associate professor and Russell C. McCarthy Endowed Professor in RIT’s College of Engineering Technology.

His explanation captures the growing industrial demand for such advancements. 3D printing has already revolutionized how complex components are made, but even the most advanced printed materials face issues with durability. Over time, exposure to stress, heat, or repeated use can lead to small cracks that expand into failures. The self-healing materials being developed at RIT aim to prevent this kind of degradation, potentially saving manufacturers time, money, and resources.

Lewis draws inspiration from biology to explain the concept. “When you break a bone, or cut yourself, we take it for granted that there is a self-repairing mechanism that allows for bones or skin to rejuvenate themselves, at least to some extent,” said Lewis. “We also learn that it is not true for synthetic materials or man-made objects. And our work in self-healing materials is a futuristics look at how we can develop systems that mimic those natural material properties.”

That natural analogy sits at the core of his research. Much like human tissue that regenerates, these engineered materials are designed to “heal” microscopic cracks before they can cause major failures. The result could be a new generation of 3D-printed components that last significantly longer and perform more consistently — a breakthrough with far-reaching implications for industries from aerospace to medicine.

The team’s key discovery came when they combined a thermoplastic healing agent with an ultraviolet-curable resin. This pairing not only strengthened the material but also introduced shape memory behavior, allowing it to revert to its original form after deformation. “It makes the material much stronger than it used to be. One of the problems with these soft, elastomeric materials is that they are traditionally weak. And it also engenders another type of property—shape memory behavior, and we are just starting to focus our efforts on better understanding this behavior,” said Lewis.

Funding from the U.S. Department of Defense has allowed Lewis and his team to push the limits of this technology, collaborating closely with experts at RIT’s AMPrint Center. Together, they have published multiple papers in ACS Applied Polymer Materials, Polymer, and 3D Print Industry, showcasing how ultraviolet (UV) vat polymerization of liquid resin systems can be tailored to produce stronger, self-repairing structures.

Yet, the process is anything but simple. Achieving the perfect balance between the material’s viscosity, light sensitivity, and solubility requires meticulous control. “The approach we have taken is one where we have a mixture of two different things. We have our photoreactive, thermosetting polymer that once cured becomes a soft rubber. To this, we also add a thermoplastic healing agent. We were able to get light to pass through the system, and we achieved that by utilizing polymerization induced phase separation (PIPS). It is a process where the thermoset and thermoplastic materials separate during curing,” he said. “That is key to this whole thing.”

Polymerization induced phase separation — or PIPS — is central to how this self-healing process works. In this mechanism, the mixture starts as a single optically clear liquid that allows light to pass through. As the curing begins, the two materials separate, forming a distinct structure within the printed layers. Lewis likens this transformation to the mesmerizing movement inside a lava lamp, where heat and light trigger continuous shifts in form and flow.

“Earlier work on thermoplastic polymer blends that are able to be processed using conventional techniques like injection molding or extrusion suggested that it was that phase separation that seemed to be driving the self-healing behavior of those systems. That understanding led us down this path of experimentation with this same healing agent and photo reactive polymer system, and then, a little bit of luck,” said Lewis.

That “little bit of luck” has opened up a big opportunity. With every experiment, the researchers inch closer to a future where 3D-printed parts can sustain themselves without manual repair or replacement. Such technology could redefine expectations for how products are made and maintained — from aircraft components that repair minor damage midflight to prosthetic limbs that automatically restore their integrity over time.

The promise of self-healing materials lies not only in their functionality but also in their sustainability. By extending the lifespan of products and reducing waste, these innovations align with broader goals of responsible manufacturing. And as research like Lewis’s continues to advance, the line between living systems and synthetic materials grows ever thinner — a glimpse into a future where machines might one day heal themselves just as living organisms do.

-

Local News12 months ago

Local News12 months agoNew ALDI store close to Rochester to begin construction in late 2025 or early 2026

-

Local News11 months ago

Local News11 months agoRochester Lilac Festival announces exciting 127th edition headliners

-

Local News9 months ago

Local News9 months agoCounty Executive Adam Bello and members of the county legislature celebrate exceptional young leaders and advocates at the 2025 Monroe County Youth Awards

-

Local News9 months ago

Local News9 months agoThe 2025 Public Market Food Truck Rodeo series will begin this Wednesday with live music by the Royal Bromleys