Local News

Graduate uses his education to invent a groundbreaking device that is set to improve the future of dairy farming

Rochester, New York – When Jayden Neal enrolled at Rochester Institute of Technology (RIT), he had a strong sense of where his future would lead him — back home to his family’s dairy farm. But what he didn’t predict was that he would return with something more than just a degree. He would come home with a groundbreaking product poised to change the way dairy farms operate.

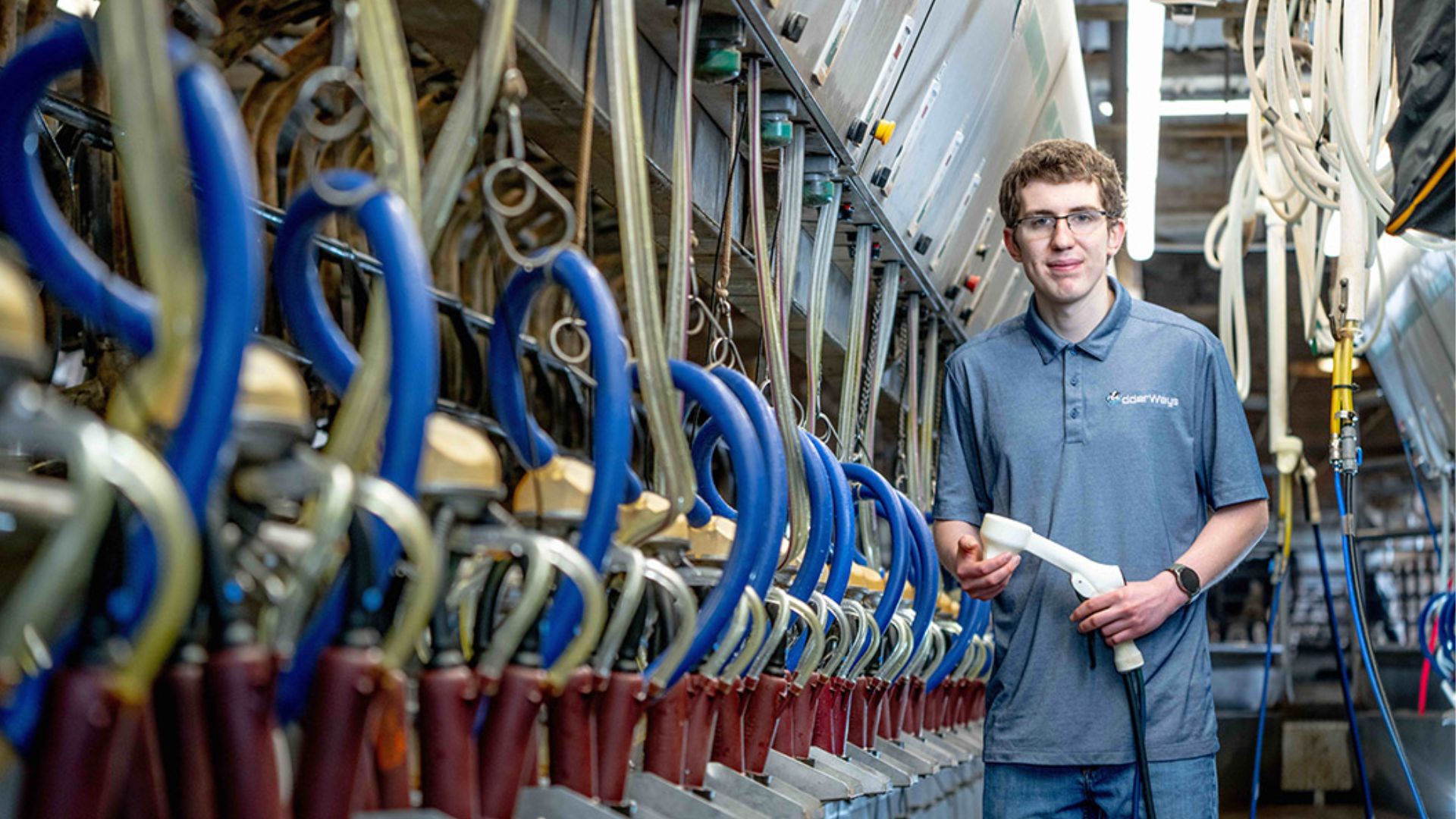

Neal, who will soon graduate with a bachelor’s degree in robotics and manufacturing engineering technology from RIT’s College of Engineering Technology, is the mind behind the Vortex, a new udder washing and sterilization system. Designed to be lightweight and more ergonomic than traditional systems, the Vortex also features improved nozzle and grip functions that make it easier and safer for farmworkers to use. It’s the first product from his family’s startup company, UdderWays, and one that is already stirring interest beyond their own farm.

“I got exposure to a lot of the tools, processes, and methodology engineers use. It was really helpful having that knowledge and reinforcement, things like information in the circuits courses and PCB design led to developing a more efficient control system,” said Neal.

Read also: Thousands come together to celebrate groundbreaking technology and vibrant creativity at Imagine RIT

Growing up on the Orleans Poverty Hill Farm in Albion, New York, Neal was no stranger to the day-to-day challenges of dairy farming. By the time he was just 13 years old, he was already trying to think of ways to improve the milking equipment used to care for their herd of more than 600 cows. It wasn’t until he combined his early experiences with the skills he gained at RIT that he could bring a new invention to life.

“We are a third-generation dairy farm. We have quite a history here,” Neal said. “We always wanted to try to make things more efficient and try new things.”

The traditional preparation process for milking involves several time-consuming steps, including applying sanitizer, drying the udders, and stimulating milk flow. Each of these steps must be performed carefully to prevent contamination and ensure cow health. With the Vortex, Neal and his father, Jody, set out to design a system that could combine these actions into one smooth operation.

Neal took his father’s early design ideas, sketched out on paper, and used modern engineering techniques to bring them to life. He experimented with different prototypes, 3D printing parts to test their function. Together, they also moved away from traditional brushes, which can sometimes injure cows, in favor of a gentler fluid-whirling method. The result is a patented, handheld device that not only saves time but also makes the process safer for both cows and workers.

“Students come to programs like ours in the College of Engineering Technology looking to take fundamental engineering principles and apply them to solve practical problems,” said Beth Carle, professor and department head of manufacturing and mechanical engineering technology. “Jayden is an example of this success. He has used his analytical skills to identify a problem affecting not only his family’s farm, but the broader dairy industry, and then applied his technical and entrepreneurial skills to solve the problem.”

And the dairy industry is no small operation. New York state alone is home to more than 3,000 dairy farms, from small boutique producers to large-scale operations. Together, they produce nearly 15 billion pounds of milk each year, making New York the fifth-largest dairy producer in the United States.

Recognizing the potential for the Vortex to meet a real need in this vast industry, UdderWays has already seen success beyond the farm. The company recently earned a $500,000 award from the Grow-NY Food & Agriculture Startup Competition, a major boost as they move toward full commercialization of the product.

Through an accelerator program with REV: Ithaca Startup Works, Neal has been navigating the complex path of bringing a new product to market. He is tackling business needs like securing proper certifications and finding a manufacturing partner to handle injection molding for mass production.

“People have been seeking alternatives and that led to other products, but those other products had some drawbacks, which kind of opened the door for us,” he said. “It showed a need for the product, and we are having a ridiculous amount of demand for this right now. We really hope to meet that soon.”

The fast-rising demand has only strengthened Neal’s excitement for what lies ahead. His education at RIT, he said, played a major role in giving him the knowledge and hands-on experience he needed to succeed.

“I found that at RIT, there was such a wide variety of classes, clubs, and a lot of industry experiences. Those were some of the key reasons for me coming here and it’s been great,” Neal said. “Our company, it’s nothing I ever would have predicted, but it excites me that we are able to succeed, to get something out there that farmers like. Hopefully this might lead to more products down the road.”

As UdderWays prepares to launch its first device into the broader market, Neal’s story stands as an example of what can happen when innovation meets tradition. With roots deeply planted in his family’s farming history and eyes set on the future of dairy technology, he is ready to help farms big and small work smarter, safer, and more efficiently.

-

Local News12 months ago

Local News12 months agoNew ALDI store close to Rochester to begin construction in late 2025 or early 2026

-

Local News12 months ago

Local News12 months agoRochester Lilac Festival announces exciting 127th edition headliners

-

Local News10 months ago

Local News10 months agoCounty Executive Adam Bello and members of the county legislature celebrate exceptional young leaders and advocates at the 2025 Monroe County Youth Awards

-

Local News10 months ago

Local News10 months agoThe 2025 Public Market Food Truck Rodeo series will begin this Wednesday with live music by the Royal Bromleys